Automobile Damping and Silencing Sheet SS2013208

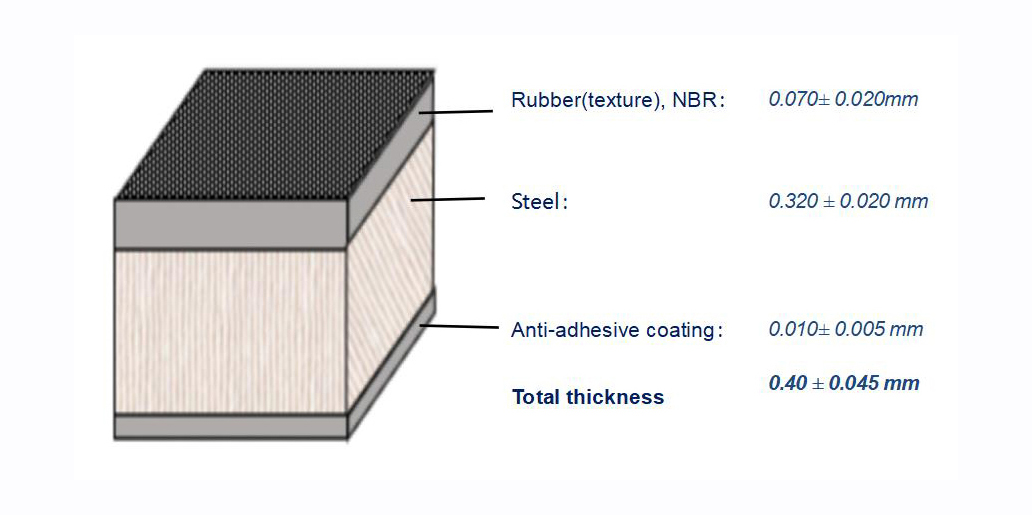

Products Specification

| Corrosion | ·Level 0-2 according to ISO2409 -measured according to VDA-309 ·The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | ·The maximum instantaneous temperature resistance is 220℃ ·48 hours of conventional temperature resistance of 130 ℃ ·Minimum temperature resistance -40℃ |

| MEK Test | · MEK = 100 surface without falling off cracking |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

Automobile Damping & Silencing Pads

These pads mitigate braking noise by absorbing vibrations generated between the friction plate and brake disc. Positioned on the steel backing, they reduce sound wave intensity through layered phase resistance and resonance avoidance, ensuring quieter braking and improved ride comfort. The brake system comprises friction lining (friction material), steel backing (metal substrate), and damping/silencing pads.

Silencing Principle

Noise arises from friction-induced vibrations between the friction plate and brake disc. The silencing pad’s layered structure disrupts sound wave propagation, leveraging phase resistance and resonance cancellation to reduce noise levels effectively.

Products Feature

High-Performance Rubber-Coated Steel Plates for Industrial Applications

Our advanced rubber-coated steel plates feature exceptional adhesion strength, engineered to withstand extreme temperatures (-40°C to +200°C) and exposure to engine oils, antifreeze, coolants, and other industrial fluids. The precision-engineered substrate combines:

Uniform thickness distribution across both steel core and rubber coating

Smooth, flaw-free surfaces with rust-proof treatment

Enhanced corrosion resistance for long-term durability

Key Advantages:

• Superior sealing performance for gas/liquid containment

• Outstanding temperature resilience (high & low) with anti-aging properties

• Optimized compression recovery & stress relaxation characteristics

• Customizable noise-damping solutions via Constrained Layer Damping (CLD) technology

Premium CLD Laminates for Noise Control

As specialized metal-rubber vulcanized composites, our vibration-damping sheets deliver:

Structural noise reduction up to 70% in critical engine components

Precision cutting/formability for complex surfaces

Press-vulcanized construction for maximum bond integrity

Industry-Proven Applications:

• Engine protection systems: Transmission covers, valve covers, chain cases, oil pans

• Custom gaskets & seals for automotive/industrial equipment

• Vibration-sensitive machinery components

Manufactured using ISO-certified processes, we provide tailored solutions for OEMs and aftermarket requirements. Request material specs or discuss custom projects via [CTA button/link].

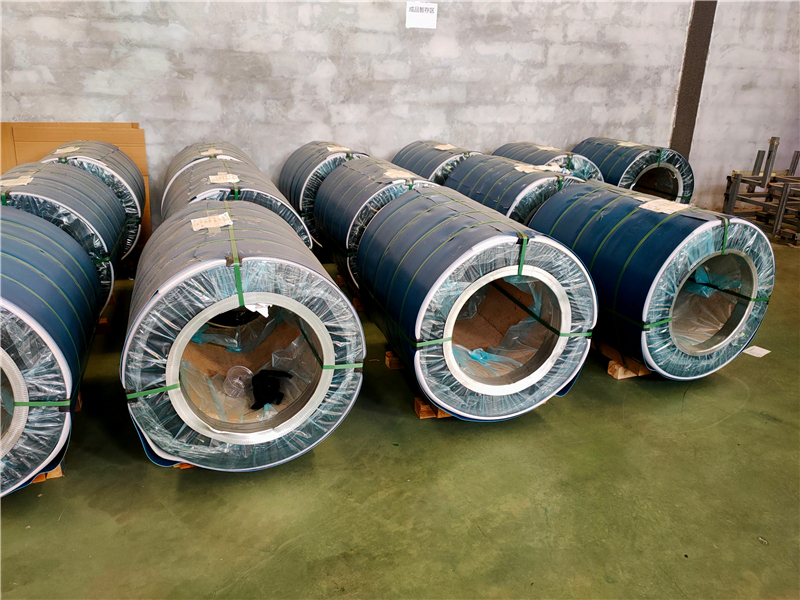

Factory Pictures

We have independent refining workshop, cleaning steel workshop, slitting car rubber, the total length of the main production line reaches more than 400 metres, so that every link in the production of their own hands, so that customers feel at ease.

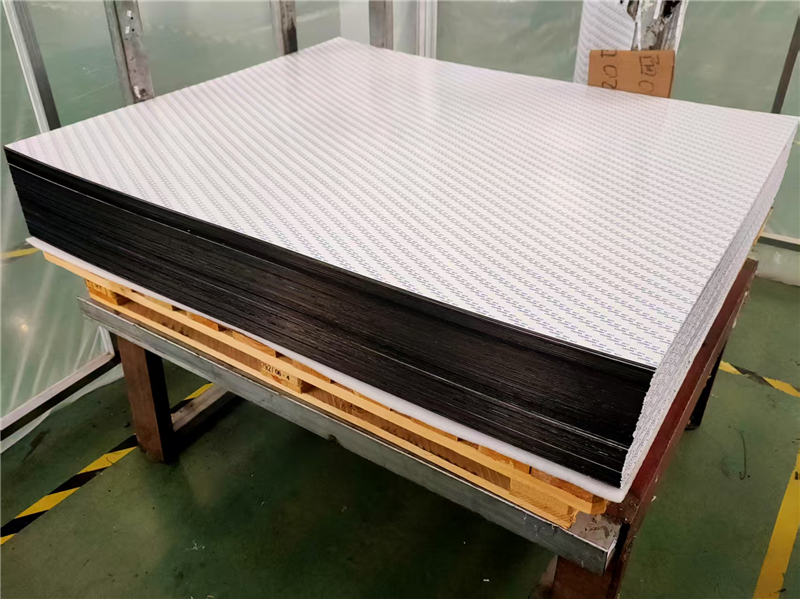

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund