Automobile Damping and Silencing Sheet DC40-01A3 Red

Products Specification

| Corrosion | · Level 0-2 according to ISO2409 -measured according to VDA-309 · The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | · The maximum instantaneous temperature resistance is 220℃ · 48 hours of conventional temperature resistance of 130 ℃ · Minimum temperature resistance -40℃ |

| MEK Test | · MEK = 100 surface without falling off cracking |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

The Automotive Shock Absorbing and Sound Deadening Pad is a critical accessory designed to minimize or eliminate noise during vehicle braking. As an integral part of automobile brake pads, it is installed on the steel backing plate of brake pads. When the brake pads engage, the pad absorbs vibrations and dampens noise generated by friction between the brake pads and rotor. The automobile brake system primarily comprises three components: the friction lining (friction material), the steel backing plate (metal part), and the vibration damping and noise-elimination pads.

Silencing Principle

Brake noise occurs due to friction-induced vibrations between the friction lining and brake disc. As sound waves travel from the friction lining to the steel backing and then to the damping pad, their intensity changes twice. The layered structure, characterized by phase impedance differences and resonance avoidance, effectively reduces noise by disrupting sound wave patterns.

Product Features

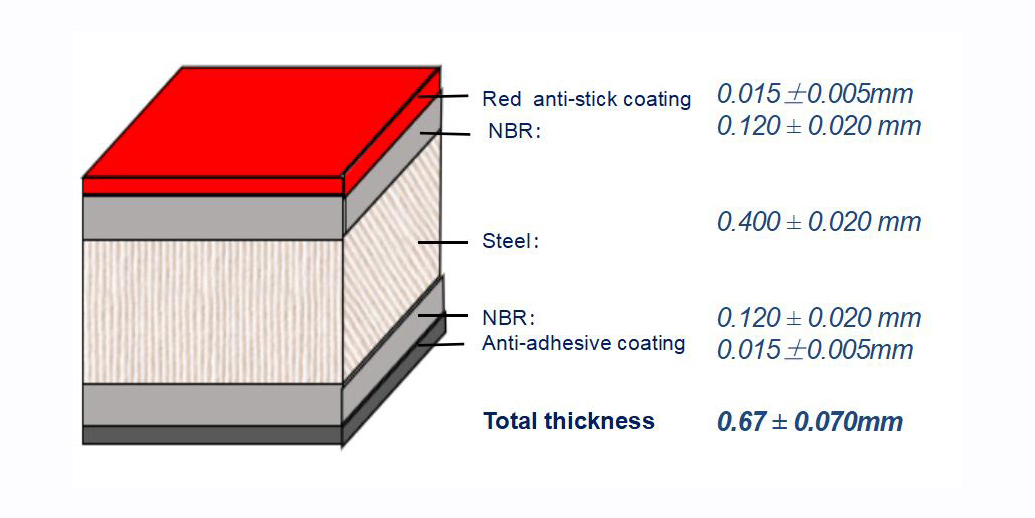

Material Specifications: The metal substrate thickness ranges from 0.2mm to 0.8mm, with a maximum width of 1000mm. The rubber coating thickness spans 0.02mm to 0.12mm. Single- and double-sided NBR rubber-coated metal materials are available to meet diverse customer needs.

Cost-Effective Solution: Serves as a reliable alternative to imported materials, offering superior vibration and noise damping performance.

Surface Treatments: Features anti-scratch coating for enhanced durability. Surface colors can be customized (red, blue, silver, etc.) to align with customer preferences. Cloth-coated sheets with a smooth finish are also available upon request.

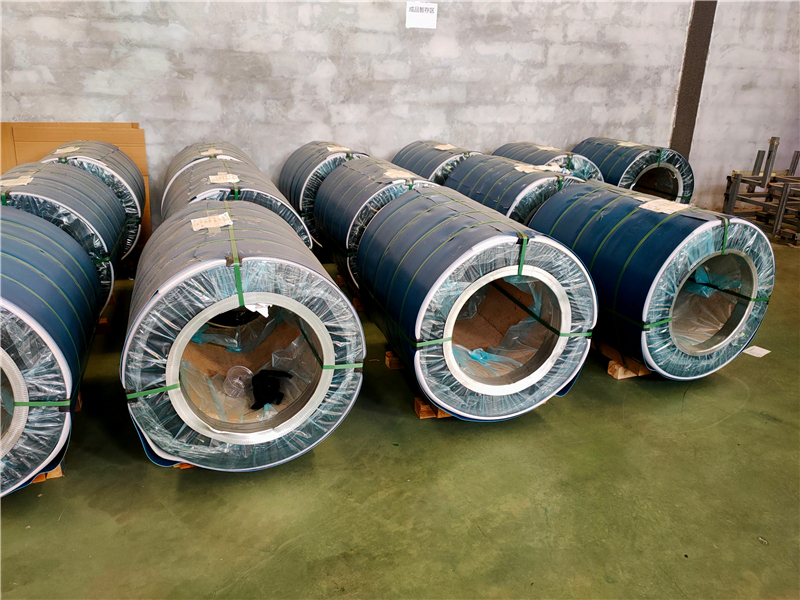

Factory Pictures

Our manufacturing facility features an independent refining workshop, a dedicated steel cleaning unit, and a precision slitting line for automotive rubber materials. The main production line spans over 400 meters, allowing us to oversee every stage of production—from raw material refining to final assembly. This hands-on approach ensures rigorous quality control and gives customers peace of mind.

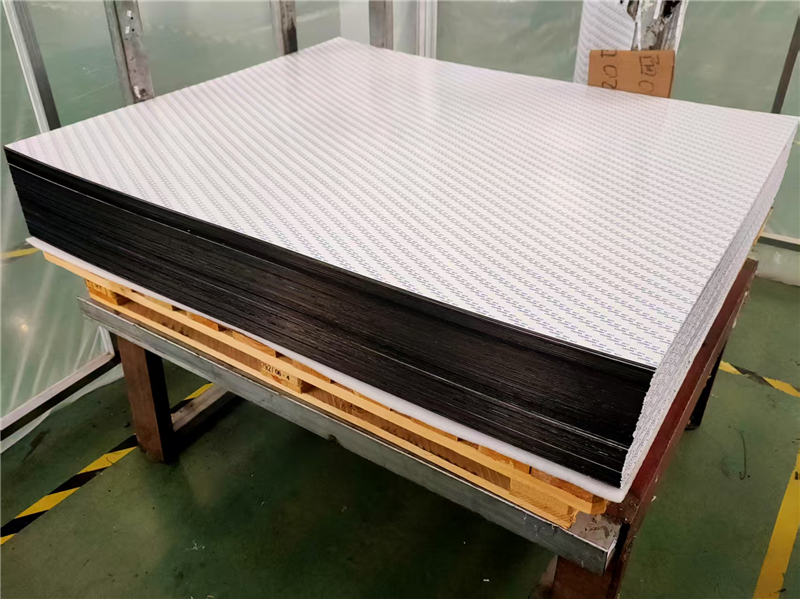

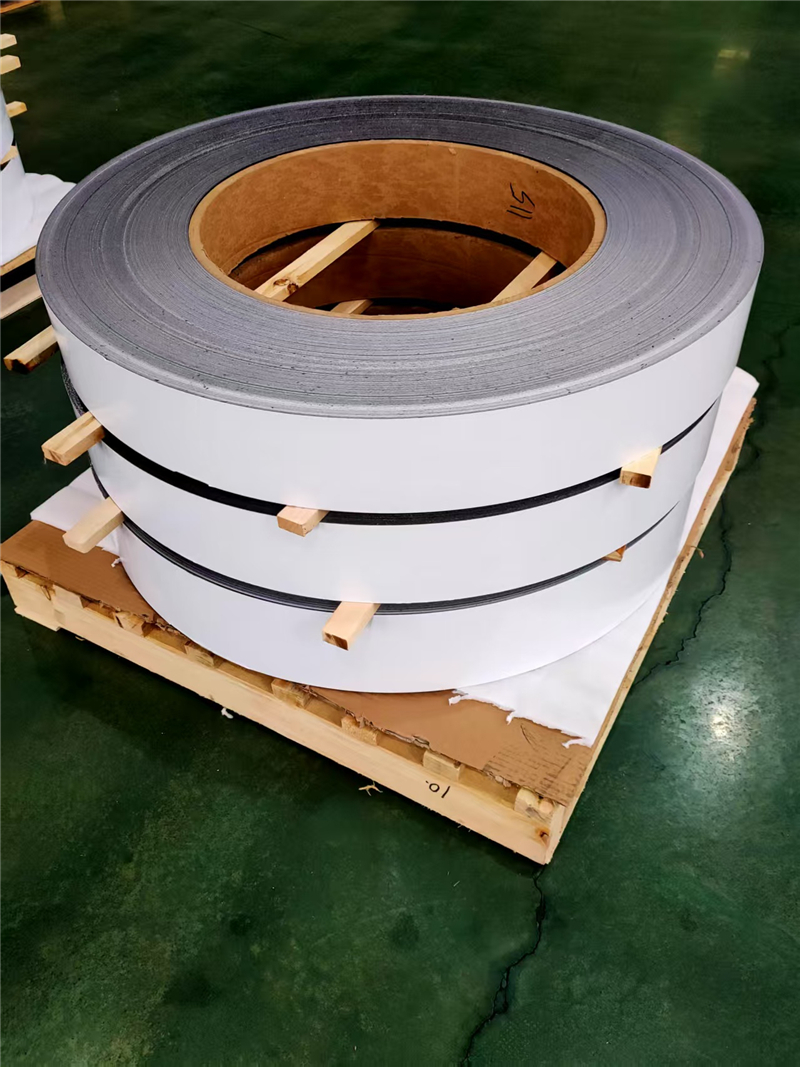

Products Pictures

Our damping materials are compatible with a wide array of pressure-sensitive adhesives (PSAs), including cold glue formulations. We offer various thicknesses of cold glue and provide customization options to suit specific requirements. Different adhesives have unique properties (e.g., temperature resistance, bonding strength), and we can process materials into rolls, sheets, or slit formats based on customer specifications.

Scientific Research Investment

Our R&D department is equipped with 20 professional testing units for silencing film materials, including advanced link testing machines. The team comprises two skilled experimenters and one certified tester. Following project completion, we plan to allocate RMB 4 million to a dedicated fund for upgrading testing and production equipment, ensuring we stay at the forefront of automotive technology.

Professional Testing Equipment

Experimenters

Tester

Special Fund