Automobile Damping and Silencing Sheet DC40-01A3 Purple

Products Specification

| Corrosion | · Level 0-2 according to ISO2409 -measured according to VDA-309 · The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | · The maximum instantaneous temperature resistance is 220℃ · 48 hours of conventional temperature resistance of 130 ℃ · Minimum temperature resistance -40℃ |

| MEK Test | · MEK = 100 surface without falling off cracking |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

Automotive shock absorbing and sound deadening pad is an accessory used to reduce or eliminate noise when braking. It is an important part of automobile brake pads and is installed on the steel backing of the brake pads. When the brake pads brake, it plays a certain role in damping the vibration and noise generated by the brake pads. The brake system mainly consists of friction lining (friction material), steel backing (metal part) and vibration damping mat.

Silencing principle: Brake noise is generated by the friction vibration between the friction lining and the brake disc. The intensity of the sound wave changes once when it passes from the friction lining to the steel backing, and again when it passes from the steel backing to the damping pad. The phase impedance between the layers and the avoidance of resonance help to reduce noise.

Product Features

The thickness of the metal substrate ranges from 0.2mm - 0.8mm with a maximum width of 1000mm and the thickness of the rubber coating ranges from 0.02mm - 0.12mm. Single and double sided NBR rubber coated metal materials are available to meet different customer requirements. It is a cost-effective alternative to imported materials with good vibration and noise damping effects.

The surface of the material has been treated with anti-scratch treatment, which has high strength and anti-scratch performance, and the surface color can be customized to red, blue, silver and other non-transferable colors according to customers' needs. According to customer demand, we can also produce cloth-coated panels without any texture.

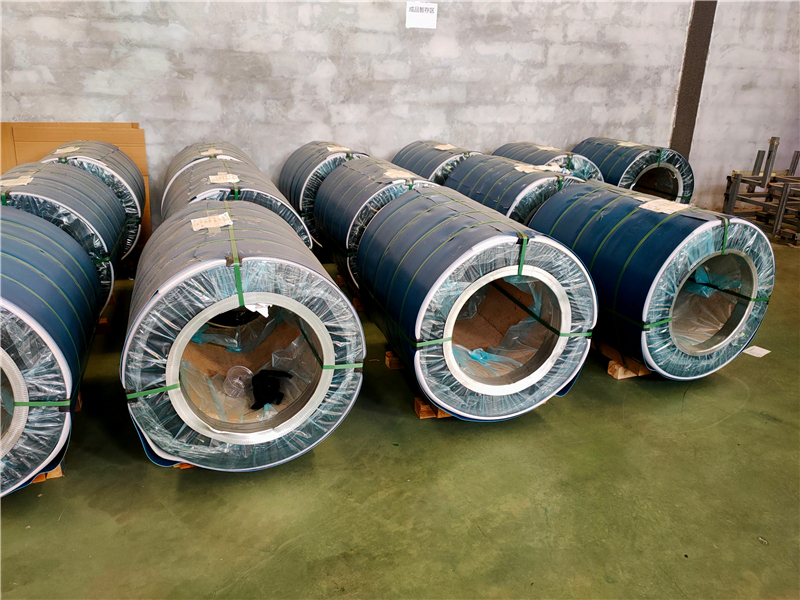

Factory Pictures

We have independent refining workshop, cleaning steel workshop, slitting car rubber, the total length of the main production line reaches more than 400 metres, so that every link in the production of their own hands, so that customers feel at ease.

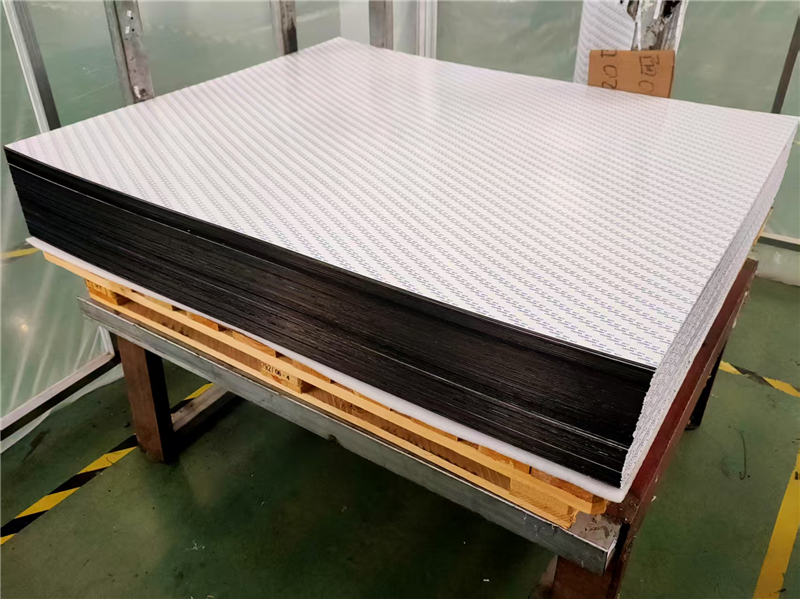

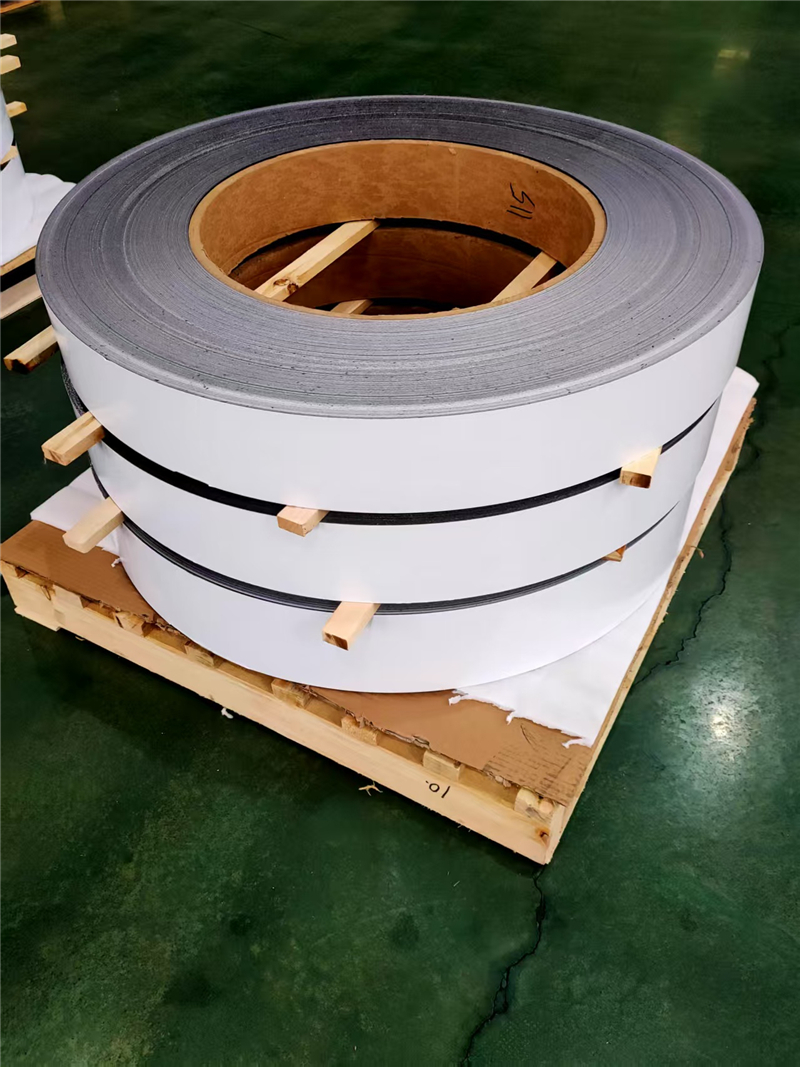

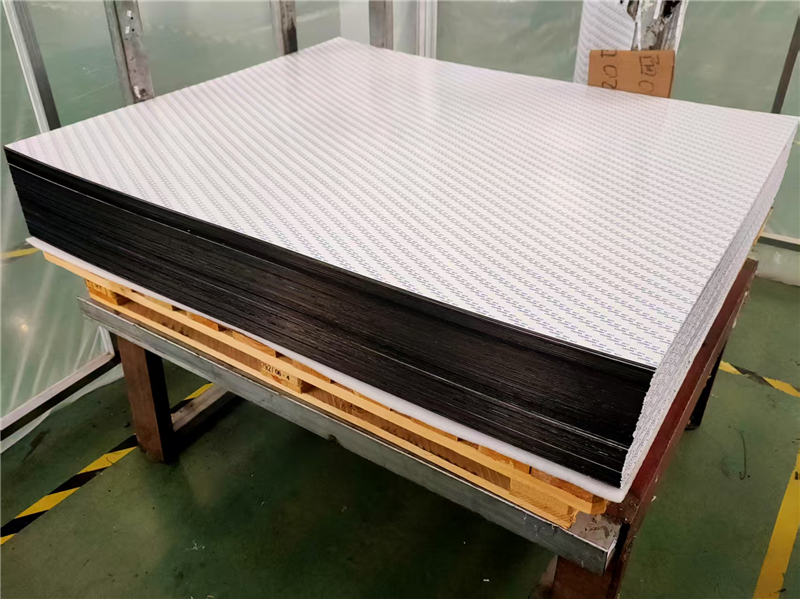

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund